TECHNICAL PAPER ON SIX STROKE ENGINES

ABSTRACT

Six Stroke engine, the name itself indicates a cycle of six strokes out of which two are useful power strokes. According to its mechanical design, the six-stroke engine with external and internal combustion and double flow is similar to the actual internal reciprocating combustion engine. However, it differentiates itself entirely, due to its thermodynamic cycle and a modified cylinder head with two supplementary chambers: combustion and an air heating chamber, both independent from the cylinder. In this the cylinder and the combustion chamber are separated which gives more freedom for design analysis. Several advantages result from this, one very important being the increase in thermal efficiency.

It consists of two cycles of operations namely external combustion cycle and internal combustion cycle, each cycle having four events. In addition to the two valves in the four stroke engine two more valves are incorporated which are operated by a piston arrangement.

The Six Stroke is thermodynamically more efficient because the change in volume of the power stroke is greater than the intake stroke and the compression stroke. The main advantages of six stroke engine includes reduction in fuel consumption by 40%, two power strokes in the six stroke cycle, dramatic reduction in pollution, adaptability to multi fuel operation.

Six stroke engine’s adoption by the automobile industry would have a tremendous impact on the environment and world economy. INTRODUCTION:

The majority of the actual internal combustion engines, operating on different cycles have one common feature, combustion occurring in the cylinder after each compression, resulting in gas expansion that acts directly on the piston (work) and limited to 180 degrees of crankshaft angle.

According to its mechanical design, the six-stroke engine with external and internal combustion and double flow is similar to the actual internal reciprocating combustion engine. However, it differentiates itself entirely, due to its thermodynamic cycle and a modified cylinder head with two supplementary chambers: Combustion, does not occur within the cylinder within the cylinder but in the supplementary combustion chamber, does not act immediately on the piston, and it’s duration is independent from the 180 degrees of crankshaft rotation that occurs during the expansion of the combustion gases (work).

The combustion chamber is totally enclosed within the air-heating chamber. By heat exchange through the glowing combustion chamber walls, air pressure in the heating chamber increases and generate power for an a supplementary work stroke. Several advantages result from this, one very important being the increase in thermal efficiency. IN the contemporary internal combustion engine, the necessary cooling of the combustion chamber walls generate important calorific losses.

In the main cylinder, combustion takes place every turn as in a two-stroke engine and lubrication as in a four-stroke engine. Fuel injection can take place in the piston charger, in the gas transfer channel or in the combustion chamber. It is also possible to charge two working cylinders with one piston charger. The combination of compact design for the combustion chamber together with no loss of air and fuel is claimed to give the engine more torque, more power and better fuel consumption. ANALYSIS OF SIX STROKE ENGINE:

Six-stroke engine is mainly due to the radical hybridization of two- and four-stroke technology. The six-stroke engine is supplemented with two chambers, which allow parallel function and results a full eight-event cycle: two four-event-each cycles, an external combustion cycle and an internal combustion cycle. In the internal combustion there is direct contact between air and the working fluid, whereas there is no direct contact between air and the working fluid in the external combustion process. Those events that affect the motion of the crankshaft are called dynamic events and those, which do not effect are called static events.

ANALYSIS OF EVENTS:

Event 1: Pure air intake in the cylinder (dynamic event)

Intake valve.

Intake valve.- Heating chamber valve

- Combustion chamber valve.

- Exhaust valve

- Cylinder

- Combustion chamber.

- Air heating chamber.

- Wall of combustion chamber.

- Fuel injector.

- Heater plug.

Event 2: Pure air compression in the heating chamber.

Event 3: Keeping pure air pressure in closed chamber where a maximum heat exchange occurs with the combustion chambers walls, without direct action on the crankshaft (static event).

Event 4: Expansion of the Super heat air in the cylinder work (dynamic Event).

Events 6: fuel injection and combustion in closed combustion chamber, without direct action on the crankshaft (static event).

Events 7: Combustion gases expanding in the cylinder, work (dynamic event).

Events 8: Combustion gases exhaust (dynamic event).

Six-stroke engine cycle diagram:

External combustion cycle: (divided in 4 events):

No direct contact between the air and the heating source.

e1. (Event 1) Pure air intake in the cylinder (dynamic event).

e2. (Event 2) Compression of pure air in the heating chamber (dynamic event).

e3. (Event 3) Keeping pure air pressure in closed chamber where a maximum heat exchange occurs with the combustion chambers walls, without direct action on the crankshaft (static event).

e4. (Event 4) Expansion of the super heated air in the cylinder, work (dynamic event).

Internal combustion cycle: (divided in 4 events)

Direct contact between the air and the heating source.

I1. (Event 5) Re-compression of pure heated air in the combustion chamber (dynamic event)

I2. (Event 6) Fuel injection and combustion in closed combustion chamber, without direct action on the crankshaft (static event).

I3. (Event 7) Combustion gases expanding in the cylinder, work (dynamic event).

I4. (Event 8) Combustion gases exhaust (dynamic event).

CONSTRUCTIONAL DETAILS:

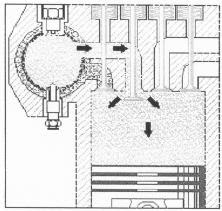

The sketches shows the cylinder head equipped with both chambers and four valves of which two are conventional (intake and exhaust). The two others are made of heavy-duty heat-resisting material. During the combustion and the air heating processes, the valves could open under the pressure within the chambers. To avoid this, a piston is installed on both valve shafts which compensate this pressure. Being a six-stroke cycle, the camshaft speed in one third of the crankshaft speed.

The combustion chambers walls are glowing when the engine is running. Their small thickness allows heat exchange with the air-heating chamber, which is surrounding the combustion chamber. The air-heating chamber is isolated from the cylinder head to reduce thermal loss.

Through heat transfer from the combustion chamber to the heating chamber, the work is distributed over two strokes, which results in less pressure on the piston and greater smoothness of operation. In addition, since the combustion chamber is isolated from the cylinder by its valves, the moving parts, especially the piston, are not subject to any excessive stress from the very high temperatures and pressures. They are also protected from explosive combustion or auto-ignition, which are observed on ignition of the air-fuel mixture in conventional gas or diesel engines.

The combustion and air-heating chambers have different compression ratio. The compression ratio is high for the heating chamber, which operates on an external cycle and is supplied solely with pure air. On the other hand, the compression ratio is low for the combustion chamber because of effectively increased volume, which operates on internal combustion cycle.

The combustion of all injected fuel is insured, first, by the supply of preheated pure air in the combustion chamber, then, by the glowing walls of the chamber, which acts as multiple spark plugs. In order to facilitate cold starts, the combustion chamber is fitted with a heater plug (glow plug). In contrast to a diesel engine, which requires a heavy construction, this multi-fuel engine, which can also use diesel fuel, may be built in a much lighter fashion than that of a gas engine, especially in the case of all moving parts.

Injection and combustion take place in the closed combustion chamber, therefore at a constant volume, over 360 degrees of crankshaft angle. This feature gives plenty of time for the fuel to burn ideally, and release every potential calorie (first contribution to pollution reduction). The injection may be split up, with dual fuel using the SNDF system (Single Nozzle, Dual Fuel). The glowing walls of the combustion chamber will calcine the residues, which are deposited there during fuel combustion (second contribution to pollution reduction).

As well as regulating the intake and exhaust strokes, the valves of the heating and the combustion chambers allow significantly additional adjustments for improving efficiency and reducing noise.

ADVANTAGES OF SIX STROKE OVER FOUR STROKE ENGINES:

The six stroke is thermodynamically more efficient because the change in volume of the power stroke is greater than the intake stroke, the compression stroke and the Six stroke engine is fundamentally superior to the four stroke because the head is no longer parasitic but is a net contributor to – and an integral part of – the power generation within exhaust stroke. The compression ration can be increased because of the absent of hot spots and the rate of change in volume during the critical combustion period is less than in a Four stroke. The absence of valves within the combustion chamber allows considerable design freedom.

Main advantages of the six-stroke engine:

Reduction in fuel consumption by at least 40%:

An operating efficiency of approximately 50%, hence the large reduction in specific consumption. the Operating efficiency of current petrol engine is of the order of 30%. The specific power of the six-stroke engine will not be less than that of a four-stroke petrol engine, the increase in thermal efficiency compensating for the issue due to the two additional strokes.

Two expansions (work) in six strokes):

Since the work cycles occur on two strokes (3600 out of 10800 ) or 8% more than in a four-stroke engine (1800 out of 720 ), the torque is much more even. This lead to very smooth operation at low speed without any significant effects on consumption and the emission of pollutants, the combustion not being affected by the engine speed. These advantages are very important in improving the performance of car in town traffic.

Dramatic reduction in pollution:

Chemical, noise and thermal pollution are reduced, on the one hand, in proportion to the reduction in specific consumption, and on the other, through the engine’s own characteristics which will help to considerably lower HC, CO and NOx emissions. Furthermore, it’s ability to run with fuels of vegetable origin and weakly pollutant gases under optimum conditions, gives it qualities which will allow it to match up to the strictest standards.

Multifuel:

Multifuel par excellence, it can use the most varied fuels, of any origin (fossil or vegetable), from diesel to L.P.G. or animal grease. The difference in inflammability or antiknock rating does not present any problem in combustion. It’s light, standard petrol engine construction, and the low compression ration of the combustion chamber; do not exclude the use of diesel fuel. Methanol-petrol mixture is also recommended.

PROTOTYPE:

Above diagrams are the pressure volume and torque angle for 6 stroke engine

CONCLUSION:

There is, at this day, no wonder solution for the replacement of the internal combustion engine. Only improvements of the current technology can help it progress within reasonable time and financial limits. The six-stroke engine fits perfectly into this view. It’s adoption by the automobile industry would have a tremendous impact on the environment and world economy, assuming up to 40% reduction in fuel consumption and 60% to 90% in polluting emissions, depending on the type of the fuel being used.

No comments:

Post a Comment